|

Ningbo Mingzhi Stainless Product Co.,Ltd

|

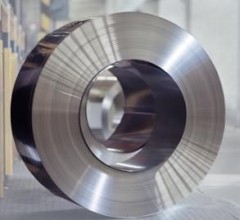

China Stainless steel coil China Stainless steel wire

| Price: | 10000.0~11000.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P, |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

The characteristics and application of 409 stainless steel:

409 stainless steel, the most inexpensive models (England), usually used in automobile

321 - not only because of the added titanium reduces the risk of weld material corrosion performance than other similar 304.

400 series - Ferritic and martensitic stainless steel

408, good heat resistance, low corrosion resistance, 11% Cr, 8% Ni.

409 - the most inexpensive models (England), usually used in automobile exhaust pipe, is a ferritic stainless steel (steel).

410 - martensite (high strength steel), good wear resistance, corrosion resistance is poor.

416 - sulfur added to improve the processing properties of materials.

420 - "cutting class" martensitic steel, similar Brinell first high-chromium stainless steel this. Also used in surgical operation tools, can do very light.

430 - ferritic stainless steel, decorative, such as for car accessories. Good shape, but heat resistance and corrosion resistance is worse.

440 - high strength cutting tool steel, carbon slightly higher, after appropriate heat treatment to obtain a higher yield strength, hardness can reach 58HRC, belongs to the most hard stainless steel column. The most common application example is the "razor blade". There are three common models: 440A, 440B, 440C, and 440F (easy processing).

500 series - resisting chromium alloy steel.

600 series of Martensite Precipitation Hardening Stainless steel.

630 - the most commonly used precipitation hardening stainless steel type, also known as 17-4 17%Cr, 4%Ni.

Related Search

Stainless Steel Wire Coil

Coil Stainless Steel

Stainless Steel Coil

Stainless Steel In Coil

Stainless Steel Coil Sheet

Polished Stainless Steel Coil

More>>